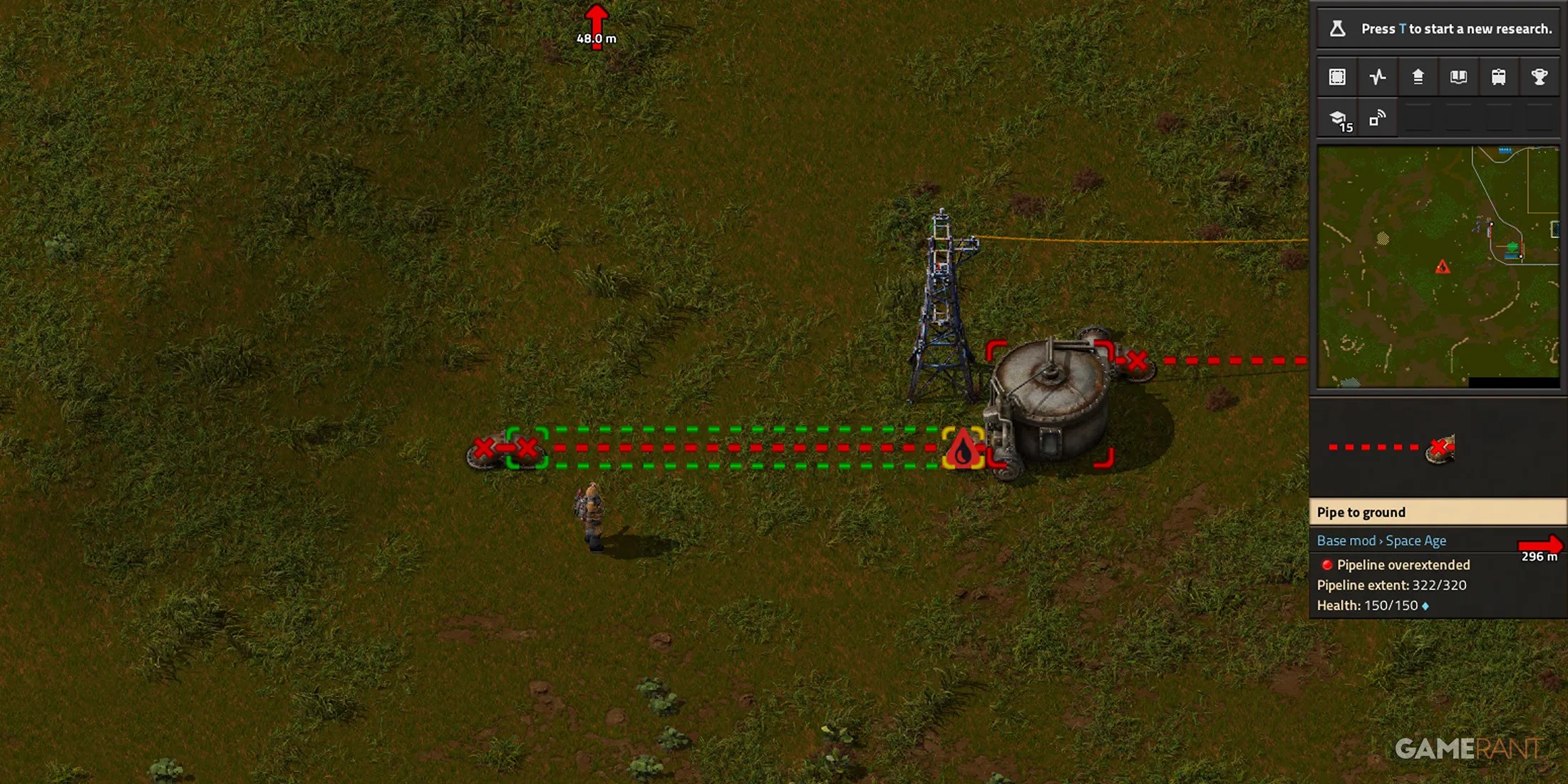

What happens when a pipeline in Factorio is overextended?

In the game Factorio, a pipeline is a structure that can be used to transport fluids, such as water, oil, or gas. Pipelines can be overextended when they are too long or when they are not connected to a pump or other source of fluid. When a pipeline is overextended, it will not be able to transport fluid efficiently, and it may even break.

There are several reasons why a pipeline might become overextended. One reason is that the player may have placed the pipeline too far away from the source of fluid. Another reason is that the player may have added too many pumps to the pipeline, which can increase the pressure and cause the pipeline to break.

If a pipeline becomes overextended, the player can try to fix it by moving the pipeline closer to the source of fluid or by removing some of the pumps. The player can also try to use a different type of pipe, such as a reinforced pipe, which is more durable and can withstand higher pressure.

Pipeline Overextended Factorio

Introduction: Pipelines are a crucial aspect of Factorio, enabling efficient transportation of fluids throughout the factory. However, overextending pipelines can lead to inefficiencies and potential risks.

Key Aspects:

- Length: Overextending pipelines beyond their recommended length can result in reduced flow rates and increased pressure, leading to potential ruptures.

- Pumps: Excessive use of pumps can create high pressure, causing pipelines to overextend and potentially break.

- Pipe Type: Using standard pipes for high-pressure applications can lead to overextension and failures. Reinforced pipes are better suited for such scenarios.

Discussion: Balancing pipeline length, pump usage, and appropriate pipe selection is crucial to prevent overextension. Proper planning and monitoring of fluid flow rates can help maintain optimal pipeline performance.

Connection between Pipeline Length and Overextension

Introduction: Pipeline length plays a significant role in overextension. Understanding the relationship between the two is essential for effective pipeline management.

Facets:

- Flow Rate: Longer pipelines result in increased resistance to fluid flow, reducing the overall flow rate.

- Pressure: As fluid travels through a longer pipeline, friction increases, leading to higher pressure buildup.

- Pipe Diameter: Wider pipes can mitigate the effects of length on flow rate and pressure, but they come with increased material costs.

Summary: Careful consideration of pipeline length is necessary to avoid overextension. Longer pipelines require additional pumps and potentially larger pipe diameters to maintain desired flow rates and prevent excessive pressure.

Connection between Pumps and Overextension

Introduction: Pumps play a vital role in fluid transportation, but excessive use can lead to pipeline overextension.

Facets:

- Pressure Increase: Pumps increase the pressure of the fluid flowing through the pipeline.

- Over-pumping: Adding too many pumps in a pipeline can result in excessive pressure, exceeding the of the pipes.

- Pump Placement: Strategically placing pumps along the pipeline can help distribute pressure more evenly, reducing the risk of overextension.

Summary: Proper pump selection and placement are crucial to prevent overextension. Over-pumping can lead to high pressure and potential pipeline failures.

Pipeline Overextended Factorio

Pipelines are crucial for efficient fluid transportation in Factorio. However, overextending pipelines can lead to inefficiencies and potential risks. Understanding the key aspects related to pipeline overextension is essential for effective pipeline management.

- Length: Excessive pipeline length increases resistance and pressure, leading to potential ruptures.

- Pumps: Over-pumping can create excessive pressure, causing pipelines to overextend and break.

- Pipe Type: Standard pipes may not withstand high pressure in overextended pipelines; reinforced pipes are more suitable.

- Flow Rate: Overextended pipelines experience reduced flow rates due to increased friction and resistance.

- Pressure Buildup: Longer pipelines and excessive pumping contribute to increased pressure buildup.

- Pipe Diameter: Wider pipes mitigate the effects of length on flow rate and pressure, but they come with higher material costs.

- Pump Placement: Strategic pump placement can distribute pressure more evenly, reducing overextension risks.

- Monitoring: Regular monitoring of fluid flow rates and pressure can help identify potential overextension issues.

These aspects are interconnected and should be considered together to prevent pipeline overextension. Balancing pipeline length, pump usage, and appropriate pipe selection is crucial. Proper planning and monitoring of fluid flow rates can help maintain optimal pipeline performance and prevent costly failures.

Length

In the context of Factorio, pipeline length is a critical factor in ensuring efficient fluid transportation. Excessive pipeline length can lead to increased resistance and pressure, which can have detrimental effects on the pipeline system.

Increased resistance in pipelines is caused by the friction between the fluid and the pipe walls. As the length of the pipeline increases, so does the friction, which hinders the flow of the fluid. This can lead to a reduction in the flow rate, making it difficult to meet the fluid demands of the factory.

Furthermore, excessive pipeline length also contributes to increased pressure buildup. As the fluid flows through the pipeline, it encounters resistance, which causes the pressure to increase. If the pressure exceeds theof the pipes, it can lead to ruptures and leaks, which can disrupt fluid transportation and cause costly downtime.

Understanding the connection between pipeline length and overextension is crucial for effective pipeline management in Factorio. By carefully considering the length of pipelines and implementing appropriate measures to mitigate resistance and pressure buildup, players can ensure the efficient and reliable operation of their fluid transportation systems.

Pumps

In the context of Factorio, pumps play a crucial role in fluid transportation, but excessive use can lead to pipeline overextension and potential ruptures.

- Pressure Increase: Pumps increase the pressure of the fluid flowing through the pipeline. This increased pressure is necessary to overcome the resistance and elevation changes in the pipeline. However, excessive pressure can put undue stress on the pipes, increasing the risk of overextension and ruptures.

- Over-pumping: Adding too many pumps in a pipeline can result in excessive pressure, exceeding the of the pipes. This over-pumping can lead to a buildup of pressure, causing the pipes to expand and potentially burst.

- Pump Placement: The placement of pumps along the pipeline is also important to consider. Strategically placing pumps can help distribute pressure more evenly, reducing the risk of overextension. For example, placing pumps at regular intervals along a long pipeline can help maintain a consistent pressure level and prevent excessive pressure buildup in any one section.

Understanding the connection between pumps and pipeline overextension is crucial for effective pipeline management in Factorio. By carefully considering the number and placement of pumps, players can ensure the efficient and safe operation of their fluid transportation systems.

Pipe Type

In the context of Factorio, the type of pipe used can significantly impact the risk of pipeline overextension, especially in scenarios involving high pressure.

Standard pipes, which are commonly used in the early stages of the game, have a lower pressure tolerance compared to reinforced pipes. When subjected to high pressure resulting from overextended pipelines or excessive pumping, standard pipes may struggle to withstand the stress, increasing the likelihood of ruptures and leaks.

Reinforced pipes, on the other hand, are specifically designed to handle higher pressure levels. Their increased durability makes them more suitable for use in overextended pipelines or in situations where high pressure is unavoidable. By utilizing reinforced pipes, players can mitigate the risk of pipeline failures and ensure the reliable transportation of fluids.

Understanding the connection between pipe type and pipeline overextension is crucial for effective pipeline management in Factorio. By carefully selecting the appropriate pipe type based on the pressure requirements and pipeline length, players can enhance the safety and efficiency of their fluid transportation systems.

Flow Rate

In the context of Factorio, understanding the relationship between flow rate and pipeline overextension is crucial for maintaining efficient fluid transportation.

- Friction and Resistance: As pipelines become overextended, the length of the pipe increases, resulting in increased friction between the fluid and the pipe walls. This friction, coupled with the resistance caused by bends and elevation changes, impedes the flow of the fluid, leading to reduced flow rates.

- Pressure Drop: Overextended pipelines experience a gradual drop in pressure as the fluid travels through the pipe. This pressure drop is caused by the frictional losses and resistance encountered along the pipeline's length. As the pressure decreases, the driving force behind the fluid flow diminishes, further contributing to reduced flow rates.

- Pipe Diameter: The diameter of the pipeline also plays a role in flow rate. Overextended pipelines with smaller diameters experience more significant flow rate reductions compared to pipelines with larger diameters. This is because narrower pipes create greater resistance to fluid flow.

- Pump Placement: The strategic placement of pumps along overextended pipelines can help mitigate reduced flow rates. Pumps can be used to increase the pressure of the fluid, compensating for the pressure drop and maintaining a higher flow rate.

By understanding the connection between flow rate and pipeline overextension, players can make informed decisions regarding pipeline design and maintenance. Careful consideration of pipeline length, diameter, and pump placement can help ensure efficient fluid transportation and prevent production bottlenecks.

Pressure Buildup

In the context of Factorio, understanding the connection between pressure buildup and pipeline overextension is crucial for maintaining safe and efficient fluid transportation systems.

- Increased Resistance: As pipelines become overextended, the length of the pipe increases, leading to increased resistance to fluid flow. This resistance causes the pressure within the pipeline to rise, potentially exceeding the of the pipes.

- Pump Overuse: Excessive use of pumps can also contribute to increased pressure buildup. Pumps are used to increase the pressure of the fluid flowing through the pipeline, but adding too many pumps can result in excessive pressure, putting undue stress on the pipes and increasing the risk of ruptures.

- Elevation Changes: Pipelines that traverse significant elevation changes can also experience increased pressure buildup. As fluid flows uphill, the pressure increases due to the weight of the fluid pushing against the lower sections of the pipeline.

- Pipe Diameter: The diameter of the pipeline plays a role in pressure buildup as well. Narrower pipelines create greater resistance to fluid flow, leading to higher pressure levels compared to wider pipelines.

By understanding the factors that contribute to pressure buildup, players can take appropriate measures to mitigate the risks associated with pipeline overextension. This may involve limiting pipeline length, avoiding excessive pumping, carefully managing elevation changes, and selecting appropriate pipe diameters.

Pipe Diameter

In the context of Factorio, understanding the relationship between pipe diameter and pipeline overextension is crucial for optimizing fluid transportation systems.

Wider pipes offer several advantages in mitigating the effects of overextended pipelines:

- Reduced Resistance: Wider pipes have a larger cross-sectional area, which reduces the resistance to fluid flow. This results in less pressure drop and higher flow rates, even in overextended pipelines.

- Lower Pressure Buildup: Wider pipes can accommodate a higher volume of fluid, reducing the pressure buildup that occurs in narrower pipes, especially over long distances.

However, wider pipes also come with some drawbacks:

- Increased Material Costs: Wider pipes require more materials to manufacture, resulting in higher construction costs.

- Space Requirements: Wider pipes occupy more space, which may be a concern in compact factory layouts.

When considering pipeline overextension, players must carefully weigh the benefits of wider pipes against the increased costs and space requirements. In scenarios where flow rate and pressure are critical, wider pipes may be a worthwhile investment. However, in situations where cost and space are primary concerns, narrower pipes may be a more practical choice.

Pump Placement

In the context of Factorio, pump placement plays a crucial role in mitigating the risks associated with pipeline overextension.

When pipelines become overextended, excessive pressure can build up within the system, potentially leading to ruptures and leaks. Strategic placement of pumps along the pipeline helps to distribute this pressure more evenly, reducing the strain on individual pipe segments.

By carefully considering the location and spacing of pumps, players can create a more balanced pressure profile throughout the pipeline. This reduces the likelihood of pressure buildup exceeding the of the pipes, minimizing the risk of overextension and ensuring the reliable flow of fluids.

For example, in a long pipeline transporting a high volume of fluid, placing pumps at regular intervals can help maintain a consistent pressure level, preventing excessive pressure buildup in any one section. Additionally, placing pumps at elevation changes can help overcome the increased pressure caused by the weight of the fluid.

Understanding the connection between pump placement and pipeline overextension is essential for effective fluid management in Factorio. By strategically placing pumps, players can optimize pipeline performance, minimize the risk of failures, and ensure the efficient and reliable transportation of fluids throughout their factory.

Monitoring

In the context of Factorio, regular monitoring of fluid flow rates and pressure is a crucial aspect of preventing pipeline overextension and ensuring efficient fluid transportation.

- Early Detection of Pressure Buildup: Monitoring pressure levels allows players to identify potential overextension issues before they become catastrophic. By observing a gradual increase in pressure, players can take proactive measures to alleviate the pressure, such as adding additional pumps or adjusting pump settings.

- Identification of Flow Rate Reductions: Monitoring flow rates can help detect reductions that may indicate pipeline overextension. Reduced flow rates can be caused by increased friction and resistance in overextended pipelines, and by identifying these issues early on, players can investigate the underlying causes and implement solutions.

- Optimization of Pump Placement: Monitoring fluid flow rates and pressure along the pipeline can provide valuable insights for optimizing pump placement. By observing the pressure distribution, players can identify sections of the pipeline that require additional pumps or adjustments to existing pump settings, ensuring a more balanced pressure profile and reducing the risk of overextension.

- Leak Detection: Regular monitoring can also help detect leaks in the pipeline system. Sudden drops in pressure or flow rates may indicate leaks, allowing players to quickly address these issues and prevent further fluid loss or contamination.

By incorporating regular monitoring of fluid flow rates and pressure into their pipeline management strategies, Factorio players can proactively identify and mitigate potential overextension issues, ensuring the reliable and efficient transportation of fluids throughout their factories.

FAQs on Pipeline Overextension in Factorio

This section addresses frequently asked questions and provides informative answers to clarify common concerns and misconceptions regarding pipeline overextension in Factorio.

Question 1: What are the key factors that contribute to pipeline overextension?

Pipeline overextension occurs when pipelines are too long, subjected to excessive pumping, or constructed using standard pipes in high-pressure scenarios. Understanding these factors is crucial for effective pipeline management.

Question 2: How does pipeline overextension impact fluid transportation?

Overextended pipelines experience reduced flow rates due to increased friction and resistance. Additionally, excessive pressure buildup can occur, leading to potential ruptures and leaks, disrupting fluid transportation and causing production inefficiencies.

Summary:

Preventing pipeline overextension in Factorio requires careful consideration of pipeline length, pump usage, and appropriate pipe selection. Regular monitoring of fluid flow rates and pressure is also essential for early detection of potential issues. By addressing these factors, players can ensure efficient and reliable fluid transportation throughout their factories.

Conclusion

Pipeline overextension in Factorio can lead to reduced flow rates, increased pressure buildup, and potential pipeline failures. To prevent these issues, it is crucial to carefully consider pipeline length, pump usage, and appropriate pipe selection. Regular monitoring of fluid flow rates and pressure is also essential for early detection of potential problems.

By understanding the factors that contribute to pipeline overextension and implementing effective mitigation strategies, players can ensure the efficient and reliable transportation of fluids throughout their factories. This not only optimizes production but also minimizes the risk of costly downtime and interruptions.

You Might Also Like

Discover The Ultimate Guide To "Rumah Perjaka": Your Gateway To Home OwnershipNikki Coxx: Full Profile And Latest News

Lincoln Marshall Marroquin: The Extraordinary Life And Legacy Of A Trailblazing Entrepreneur

The Enchanting Performances Of Richard Armitage: A Cinematic Journey

Discover The Ultimate Guide To Kawaii Softies: Craft, Collect, And Cuddle

Article Recommendations

- Get The Latest On Rod Lavers Age Tennis Legends Current Age Revealed

- Unveiling The Mystery Behind The Crazyjamjam Leak

- Unveiling The Truth Is Lyn Alden A Man