In a complex world of interconnected systems, the concept of "factorio pipeline has been overextended" stands as a critical juncture, compelling us to re-evaluate and refine our approaches to resource allocation and supply chain optimization.

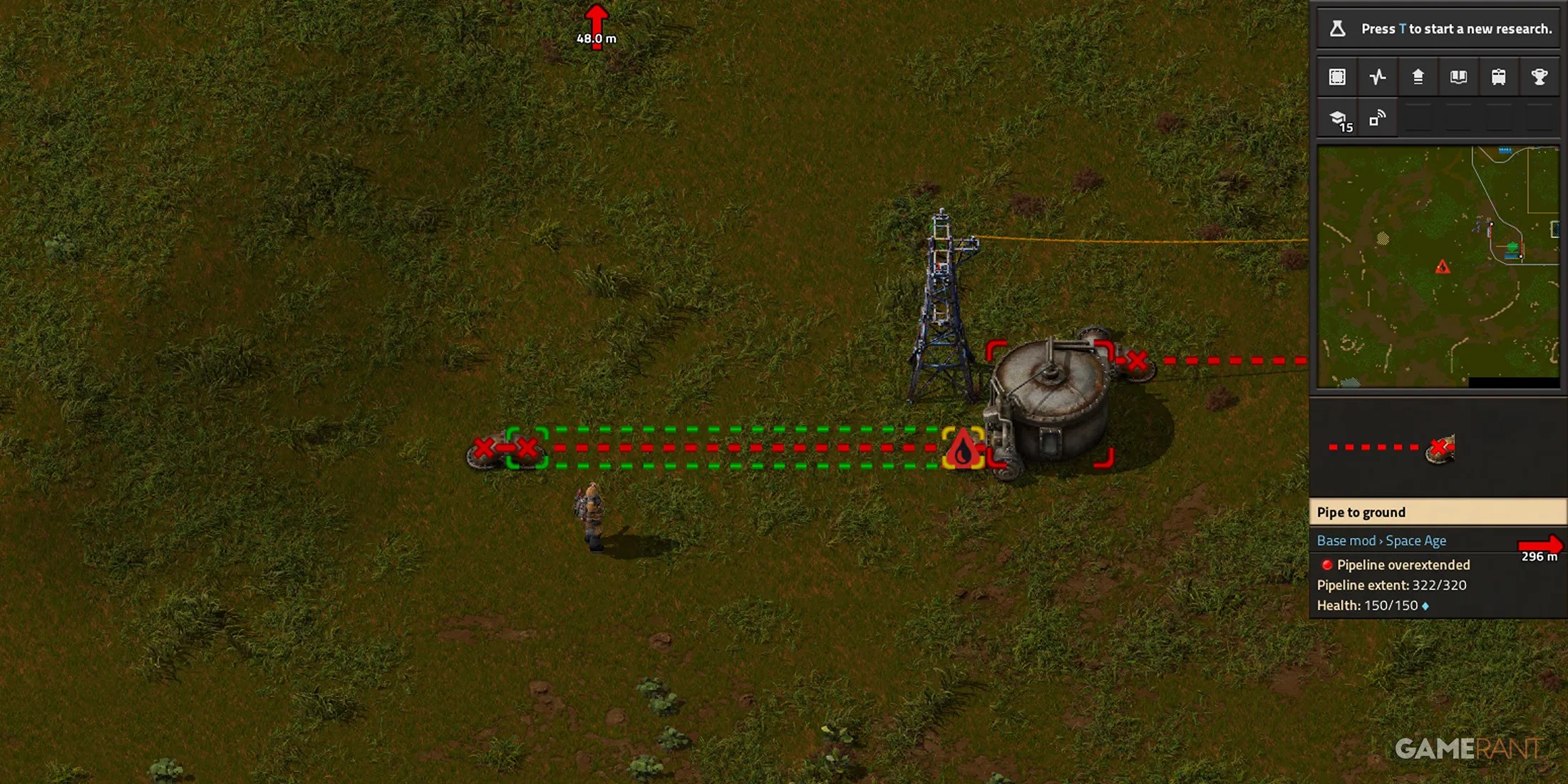

In the context of Factorio, a simulation game renowned for its intricate production and logistics systems, the term "factorio pipeline has been overextended" encapsulates the situation where the supply chain becomes overly stretched, leading to inefficiencies, bottlenecks, and potential system failure. When a pipeline is overextended, the flow of resources slows down or even grinds to a halt, impeding progress and threatening the stability of the entire production network.

Recognizing the potential consequences of an overextended pipeline is paramount for ensuring smooth and efficient operations. By identifying and addressing the root causes of pipeline overextension, organizations can minimize disruptions, optimize resource utilization, and maintain a competitive edge in their respective industries. Through proactive planning, effective coordination, and continuous improvement initiatives, it is possible to prevent or mitigate pipeline overextension, ensuring a reliable and resilient supply chain capable of meeting evolving demands.

Ultimately, understanding the concept of "factorio pipeline has been overextended" empowers individuals and organizations to make informed decisions regarding resource allocation, supply chain management, and risk mitigation. By adopting a proactive and forward-thinking approach, we can proactively address potential challenges, minimize disruptions, and harness the full potential of our production and logistics systems.

factorio pipeline has been overextended

Introduction: Highlighting the importance of the key aspects.Key Aspects: List key aspects with brief descriptions.Discussion: Detailed discussion on the key aspects, through examples, connections, or linkage to the main topic.Explore the connection between "{point}" and "factorio pipeline has been overextended" for content details list. Never use first and second-person pronouns and AI-style formalities.{point}Introduction

{point}Introduction

factorio pipeline has been overextended

In the intricate world of production and logistics, understanding the concept of "factorio pipeline has been overextended" is crucial for maintaining efficient and resilient supply chains. This article delves into eight key aspects related to this topic, exploring their significance and interconnections.

- Resource Allocation

- Demand Forecasting

- Production Capacity

- Transportation Efficiency

- Inventory Management

- Supply Chain Visibility

- Risk Mitigation

- Continuous Improvement

Each of these aspects plays a vital role in preventing or addressing pipeline overextension. Resource allocation involves optimizing the distribution of resources to meet demand without creating imbalances. Demand forecasting helps anticipate future needs and adjust production accordingly. Production capacity must align with demand to avoid bottlenecks or underutilization. Transportation efficiency ensures the smooth and timely flow of goods. Inventory management balances stock levels to minimize waste and avoid shortages. Supply chain visibility provides real-time insights into the movement of goods, enabling proactive decision-making. Risk mitigation strategies address potential disruptions and minimize their impact. Finally, continuous improvement involves ongoing monitoring and refinement of the supply chain to enhance its effectiveness.

By considering these key aspects and their interconnections, organizations can proactively manage their supply chains, prevent overextension, and ensure a reliable flow of goods and services. This leads to increased efficiency, reduced costs, and improved customer satisfaction.

Resource Allocation

Resource allocation plays a critical role in preventing pipeline overextension in Factorio. It involves the strategic distribution of resources to meet demand without creating imbalances that can lead to bottlenecks or shortages. Effective resource allocation ensures that resources are directed to the most critical areas of production, minimizing waste and maximizing efficiency.

- Prioritizing Production

In Factorio, it is crucial to prioritize the production of essential items to avoid overextending the pipeline. This means allocating resources to the production of items that are in high demand or have long production times. By focusing on these items, manufacturers can ensure a steady flow of goods and prevent shortages.

- Balancing Supply and Demand

Maintaining a balance between supply and demand is essential to prevent overextension. This involves monitoring production capacity and adjusting resource allocation accordingly. If demand exceeds supply, manufacturers may need to increase production or acquire additional resources. Conversely, if supply exceeds demand, they may need to reduce production or explore alternative uses for the surplus resources.

- Optimizing Resource Utilization

Effective resource allocation involves optimizing utilization to minimize waste. This can be achieved by carefully planning production schedules and ensuring that resources are used efficiently. For example, manufacturers can use automated systems to optimize the use of raw materials and reduce production times.

- Adapting to Changing Conditions

Resource allocation must be adaptable to changing conditions in the supply chain. Factors such as fluctuations in demand, disruptions in transportation, or changes in production capacity can impact resource availability. Effective resource allocation involves continuously monitoring these factors and adjusting allocation strategies accordingly to maintain a resilient and responsive supply chain.

By considering these facets of resource allocation, manufacturers can optimize their production processes, prevent overextension, and achieve a smooth and efficient flow of goods.

Demand Forecasting

Demand forecasting is crucial in preventing pipeline overextension in Factorio. It involves predicting future demand for goods and services, enabling manufacturers to plan production and resource allocation accordingly. Accurate demand forecasting helps avoid overproduction, which can lead to excess inventory and wasted resources, as well as underproduction, which can result in stockouts and lost sales.

- Historical Data Analysis

Analyzing historical demand data can provide valuable insights into future demand patterns. Manufacturers can use statistical techniques to identify trends, seasonality, and other factors that influence demand. By understanding these patterns, they can make informed forecasts and adjust production plans accordingly.

- Market Research

Conducting market research can help manufacturers understand the drivers of demand and anticipate changes in consumer preferences. This involves gathering information about the target market, competition, and industry trends. By staying informed about market dynamics, manufacturers can make more accurate demand forecasts and adapt their production strategies.

- Scenario Planning

Developing scenario plans for different demand scenarios can help manufacturers prepare for unexpected events or changes in the market. By considering various possibilities and their potential impact on demand, manufacturers can develop contingency plans to mitigate risks and ensure a resilient supply chain.

- Collaboration and Communication

Collaboration and communication among different departments and stakeholders is essential for effective demand forecasting. Sales, marketing, and production teams should work together to share information and insights that can improve forecast accuracy. Open communication channels and regular data sharing can help align demand forecasts with actual market conditions.

By considering these facets of demand forecasting, manufacturers can gain a better understanding of future demand, optimize production planning, and prevent pipeline overextension. Accurate demand forecasts enable proactive decision-making, reduce waste, and improve overall supply chain efficiency.

Production Capacity

Production capacity plays a critical role in preventing and addressing "factorio pipeline has been overextended." Production capacity refers to the maximum amount of goods or services that can be produced by a facility or system within a given time frame. When production capacity is insufficient to meet demand, it can lead to a situation where the pipeline becomes overextended, resulting in bottlenecks, delays, and potential shortages.

Understanding the connection between production capacity and "factorio pipeline has been overextended" is essential for ensuring a smooth and efficient supply chain. By carefully planning and managing production capacity, manufacturers can avoid overextension and its negative consequences. Here are some key considerations:

- Matching Supply and Demand

Aligning production capacity with demand is crucial to prevent overextension. Manufacturers should conduct thorough demand forecasting and analysis to determine the optimal production capacity required to meet current and future demand. By matching supply with demand, manufacturers can ensure a steady flow of goods without creating surpluses or shortages.

- Scalability and Flexibility

Production capacity should be scalable and flexible to accommodate fluctuations in demand. Manufacturers should consider investing in equipment and processes that can be easily adjusted to increase or decrease production output as needed. This flexibility allows manufacturers to respond quickly to changes in market conditions and avoid overextension.

- Continuous Improvement

Continuously monitoring and improving production efficiency is essential to prevent overextension. Manufacturers should regularly review their production processes, identify bottlenecks, and implement improvements to increase capacity and reduce lead times. By optimizing production efficiency, manufacturers can make better use of existing capacity and avoid the need for costly expansions.

By considering these factors, manufacturers can effectively manage production capacity, prevent overextension, and ensure a reliable and efficient supply chain. Understanding the connection between production capacity and "factorio pipeline has been overextended" empowers manufacturers to make informed decisions, optimize their operations, and achieve long-term success.

Transportation Efficiency

When examining the connection between "Transportation Efficiency" and "factorio pipeline has been overextended," it becomes evident that transportation efficiency plays a crucial role in preventing and mitigating pipeline overextension. Inefficient transportation can lead to delays, bottlenecks, and disruptions in the supply chain, ultimately contributing to overextension and its negative consequences.

Transportation efficiency encompasses various aspects, including optimized routing, reliable infrastructure, and effective logistics management. By optimizing transportation routes and utilizing efficient modes of transport, manufacturers can minimize transit times and reduce the risk of delays. Reliable infrastructure, such as well-maintained roads and efficient ports, ensures smooth movement of goods and prevents disruptions that can lead to overextension.

Effective logistics management involves coordinating transportation activities to minimize waste and maximize resource utilization. This includes consolidating shipments, utilizing intermodal transportation, and leveraging technology to track and monitor shipments. By optimizing logistics processes, manufacturers can improve transportation efficiency, reduce lead times, and prevent overextension.

Furthermore, transportation efficiency is closely linked to inventory management. Inefficient transportation can lead to higher inventory levels as goods are delayed in transit. Conversely, optimized transportation enables manufacturers to reduce inventory levels by ensuring a steady and reliable flow of goods. This reduces the risk of overstocking and the associated costs, such as storage and obsolescence.

In summary, transportation efficiency is a critical component of preventing and addressing "factorio pipeline has been overextended." By optimizing transportation routes, ensuring reliable infrastructure, and implementing effective logistics management, manufacturers can improve transportation efficiency, reduce lead times, and prevent disruptions that can lead to overextension. Understanding this connection empowers manufacturers to optimize their supply chains, improve customer service, and achieve long-term success.

Inventory Management

Inventory management plays a crucial role in preventing and addressing "factorio pipeline has been overextended." Ineffective inventory management can lead to overstocking or understocking, both of which can contribute to pipeline overextension and its associated negative consequences.

Overstocking occurs when a manufacturer holds more inventory than necessary, leading to increased storage costs, potential obsolescence, and reduced cash flow. Understocking, on the other hand, occurs when a manufacturer does not have sufficient inventory to meet demand, resulting in lost sales, customer dissatisfaction, and potential production disruptions.

Effective inventory management involves maintaining optimal inventory levels to meet demand without overstocking or understocking. This requires careful planning, forecasting, and coordination throughout the supply chain. Manufacturers should utilize inventory management techniques such as just-in-time (JIT) inventory, safety stock management, and inventory optimization software to ensure efficient inventory management.

Just-in-time (JIT) inventory is a lean manufacturing technique that aims to minimize inventory levels by producing goods only when they are needed. This reduces storage costs, frees up cash flow, and minimizes the risk of obsolescence. Safety stock management involves maintaining a buffer of inventory to mitigate the risk of stockouts due to unexpected fluctuations in demand or supply. Inventory optimization software utilizes data analysis and algorithms to determine optimal inventory levels, reorder points, and safety stock levels.

By implementing effective inventory management practices, manufacturers can reduce the risk of overstocking and understocking, prevent pipeline overextension, and improve overall supply chain efficiency. This leads to reduced costs, improved customer service, and increased profitability.

Supply Chain Visibility

Supply chain visibility plays a critical role in preventing and addressing "factorio pipeline has been overextended." It refers to the ability to track and monitor the flow of goods and information throughout the supply chain, providing manufacturers with real-time insights into their operations. Lack of supply chain visibility can lead to inefficiencies, delays, and disruptions, ultimately contributing to pipeline overextension.

Enhanced supply chain visibility enables manufacturers to identify and address potential bottlenecks and disruptions before they escalate into major problems. By having real-time visibility into inventory levels, production schedules, and transportation activities, manufacturers can make informed decisions and take proactive measures to prevent overextension. For example, if a manufacturer identifies a potential delay in the delivery of raw materials, they can adjust production schedules or explore alternative sourcing options to minimize the impact on their production pipeline.

Supply chain visibility is also crucial for effective inventory management. With real-time data on inventory levels, manufacturers can optimize stock levels to avoid both overstocking and understocking. This helps prevent the accumulation of excess inventory, which can lead to storage costs, obsolescence, and reduced cash flow. Additionally, improved visibility enables manufacturers to better coordinate with suppliers and logistics providers, ensuring a smooth and efficient flow of goods.

In summary, supply chain visibility is a critical component of preventing and addressing "factorio pipeline has been overextended." By providing manufacturers with real-time insights into their operations, supply chain visibility enables proactive decision-making, reduces the risk of disruptions, and optimizes inventory management. This leads to improved supply chain efficiency, increased customer satisfaction, and reduced costs.

Risk Mitigation

Risk mitigation plays a critical role in preventing and addressing "factorio pipeline has been overextended." It involves identifying, assessing, and taking steps to reduce the likelihood and impact of potential risks that can disrupt the supply chain and lead to overextension.

- Proactive Risk Identification

Proactively identifying potential risks is crucial for effective risk mitigation. This involves conducting thorough risk assessments, analyzing historical data, and monitoring industry trends to anticipate potential disruptions. By identifying risks early on, manufacturers can develop contingency plans and take proactive measures to minimize their impact.

- Supplier Diversification

Supplier diversification involves reducing reliance on a single supplier for critical components or raw materials. By diversifying their supplier base, manufacturers can mitigate the risk of disruptions caused by supplier failures, production delays, or quality issues. This strategy helps ensure a continuous flow of goods and prevents overextension caused by supply shortages.

- Inventory Buffer

Maintaining an inventory buffer acts as a safety net against unexpected disruptions or fluctuations in demand. By holding additional inventory, manufacturers can absorb shocks caused by supply chain disruptions or sudden increases in demand. This buffer helps prevent stockouts and production stoppages, reducing the risk of pipeline overextension.

- Cross-Training and Redundancy

Cross-training employees and implementing redundancy in critical processes can mitigate the risk of disruptions caused by staff shortages or unexpected events. By ensuring that multiple employees are trained to perform essential tasks, manufacturers can maintain production schedules even when faced with absenteeism or staff turnover. Redundancy in critical processes, such as having backup systems or alternative production lines, further enhances resilience and prevents overextension.

By implementing these risk mitigation strategies, manufacturers can proactively address potential disruptions, reduce the likelihood of pipeline overextension, and ensure a more resilient and efficient supply chain. Effective risk mitigation enables manufacturers to respond quickly to unexpected events, minimize the impact of disruptions, and maintain a competitive edge in the face of uncertainty.

Continuous Improvement

In the realm of supply chain management, continuous improvement stands as a cornerstone for preventing and addressing "factorio pipeline has been overextended." It involves the ongoing process of identifying inefficiencies, implementing improvements, and striving for operational excellence throughout the supply chain.

- Process Optimization

Continuous improvement involves optimizing processes to eliminate waste, reduce lead times, and increase efficiency. By analyzing existing processes, manufacturers can identify bottlenecks, redundancies, and areas for improvement. Implementing process improvements, such as automation, lean manufacturing techniques, and employee training, can significantly reduce the risk of pipeline overextension.

- Technology Adoption

Embracing technological advancements is a key aspect of continuous improvement. Utilizing supply chain management software, data analytics, and automation tools can streamline operations, improve visibility, and enhance decision-making. By leveraging technology, manufacturers can proactively identify potential risks, optimize inventory levels, and prevent disruptions that could lead to pipeline overextension.

- Employee Engagement

Engaging employees in continuous improvement initiatives is crucial for long-term success. Encouraging employee feedback, empowering them to identify and resolve issues, and providing training opportunities can foster a culture of innovation and improvement. Engaged employees are more likely to identify inefficiencies and suggest solutions, ultimately contributing to a more efficient and resilient supply chain.

- Performance Monitoring

Continuous improvement requires ongoing monitoring of performance metrics to track progress and identify areas for further improvement. Establishing key performance indicators (KPIs) and regularly measuring performance against these metrics enables manufacturers to identify trends, evaluate the effectiveness of improvement initiatives, and make data-driven decisions to prevent pipeline overextension.

By embracing continuous improvement, manufacturers can proactively address potential risks, optimize processes, and foster a culture of innovation throughout the supply chain. This ongoing pursuit of operational excellence helps prevent and mitigate "factorio pipeline has been overextended," leading to a more efficient, resilient, and competitive supply chain.

FAQs on "Factorio Pipeline Has Been Overextended"

This section addresses frequently asked questions related to the concept of "factorio pipeline has been overextended," providing clear and informative answers to enhance understanding.

Question 1: What are the key indicators that a pipeline has become overextended?

When a pipeline becomes overextended, several indicators may emerge, including:

- Delays and bottlenecks in production and delivery

- Increased inventory levels, leading to storage constraints and potential obsolescence

- Reduced production efficiency due to disruptions and inefficiencies

- Increased costs associated with overtime, expedited shipping, and inventory carrying

Question 2: How can manufacturers prevent or mitigate pipeline overextension?

Preventing or mitigating pipeline overextension requires a comprehensive approach, including:

- Accurate demand forecasting to align production with market needs

- Efficient inventory management to optimize stock levels and minimize waste

- Supplier diversification to reduce reliance on individual suppliers and mitigate supply chain risks

- Continuous improvement initiatives to identify and address inefficiencies and bottlenecks

- Investment in technology to enhance visibility, automate processes, and improve decision-making

Summary: Understanding the concept of "factorio pipeline has been overextended" is crucial for maintaining efficient and resilient supply chains. By recognizing the indicators of overextension and implementing proactive measures, manufacturers can prevent disruptions, optimize resource allocation, and achieve long-term success.

Conclusion

The concept of "factorio pipeline has been overextended" serves as a critical reminder of the challenges and opportunities in supply chain management. Understanding the causes and consequences of pipeline overextension empowers manufacturers with the knowledge and tools to prevent or mitigate this issue effectively.

By implementing proactive measures such as accurate demand forecasting, efficient inventory management, supplier diversification, continuous improvement, and technology adoption, manufacturers can enhance supply chain visibility, optimize resource allocation, and ensure a smooth flow of goods and services. Addressing pipeline overextension is not merely a reactive response to disruptions; it is a proactive investment in supply chain resilience and long-term competitiveness.

You Might Also Like

Comprehensive Guide To Vegamovies In Hollywood: A Cinephile's HavenLatest Hollywood Hindi Dubbed Movies | Watch Online On Vegamovies

The Enigmatic Case Of Scott Lee Peterson: The Controversial Trial And Aftermath

Peter Dante's Impressive Wealth: A Peek Into His Net Worth

The Enchanting Performances Of Richard Armitage: A Cinematic Journey

Article Recommendations

- Unveiling The Mystery Behind The Crazyjamjam Leak

- Kris Murry The Ultimate Guide To Discovering The Amazing Photographer

- Top Boise State Head Coach Football Updates